Mau oyamba a Zida Zamphamvu Zamagetsi

Zida zamphamvu zamaginito, makamaka maginito okhazikika monga neodymium iron boron (NdFeB) ndi samarium cobalt (SmCo), zakhala zikugwiritsidwa ntchito kwambiri m'makampani amakono chifukwa champhamvu zawo zamaginito komanso magwiridwe antchito abwino kwambiri. Kuchokera pama motors kupita ku zida zamankhwala, kuchokera kumagetsi ogula kupita kumlengalenga, zida izi zimagwira ntchito yofunika. Ngakhale kuti maginito amphamvu amagwiritsidwa ntchito m’madera ambiri, kuopsa kwawo sikunganyalanyazidwe. Tiyeni tiphunzire momwe zida za maginito zimapangidwira, kumvetsetsa bwino zoopsa zomwe zingatheke, ndikuzipewa bwino.

Momwe maginito amphamvu amabadwira

1. Kukonzekera zakuthupi: Gawo loyamba popanga zida zamphamvu zamaginito ndikukonza zida. Kwa NdFeB, zida zazikulu zopangira zikuphatikizapo neodymium, chitsulo, boron ndi zinthu zina monga dysprosium ndi praseodymium. Zopangirazo ziyenera kufufuzidwa mosamalitsa ndikukonzedwa kuti zitsimikizire kuti chiyero ndi chiŵerengero cha kamangidwe chikugwirizana ndi zofunikira.

2. Kusungunuka: Zopangira zokonzedwa zimayikidwa mu ng'anjo ya vacuum induction kuti zisungunuke kupanga aloyi. Pochita izi, kuwongolera kutentha ndikofunikira kwambiri ndipo nthawi zambiri kumafunika kutenthedwa kwambiri kuposa 1000 ° C. The smelted alloy madzi adzatsanulidwa mu nkhungu kuziziritsa ndi kupanga ingot.

3.Kuphwanya ndi kupera: Ingot yoziziritsidwa imayenera kuthyoledwa m'zidutswa ting'onoting'ono ndi chophwanyira kenaka n'kukanthidwanso kukhala ufa wabwino ndi mphero. Kukula kwa tinthu ta ufa wabwino kumakhudza mwachindunji ubwino wa ndondomeko yotsatira, choncho sitepe iyi ndi yofunika kwambiri.

4. Kukanikiza orientation: Ufa wabwino umakwezedwa mu nkhungu ndiyeno umalunjika ndi kukanikizidwa pansi pa mphamvu ya maginito yamphamvu. Izi zimatsimikizira kuti njira ya maginito ufa particles ndi yogwirizana, motero kumapangitsa kuti maginito apangidwe. Chogulitsidwacho pambuyo pa kukanikiza kolunjika kumatchedwa "thupi lobiriwira".

5. Sintering: Thupi lobiriwira limayikidwa mu ng'anjo ya sintering ndi sintered pa kutentha kwakukulu (pafupifupi 1000 ° C-1100 ° C) kuti likhale lolimba ndikupanga maginito wandiweyani. Panthawi ya sintering, zinthuzo zimakhala zovuta kusintha thupi ndi mankhwala, ndipo pamapeto pake zimapanga chinthu chomaliza chokhala ndi maginito apamwamba.

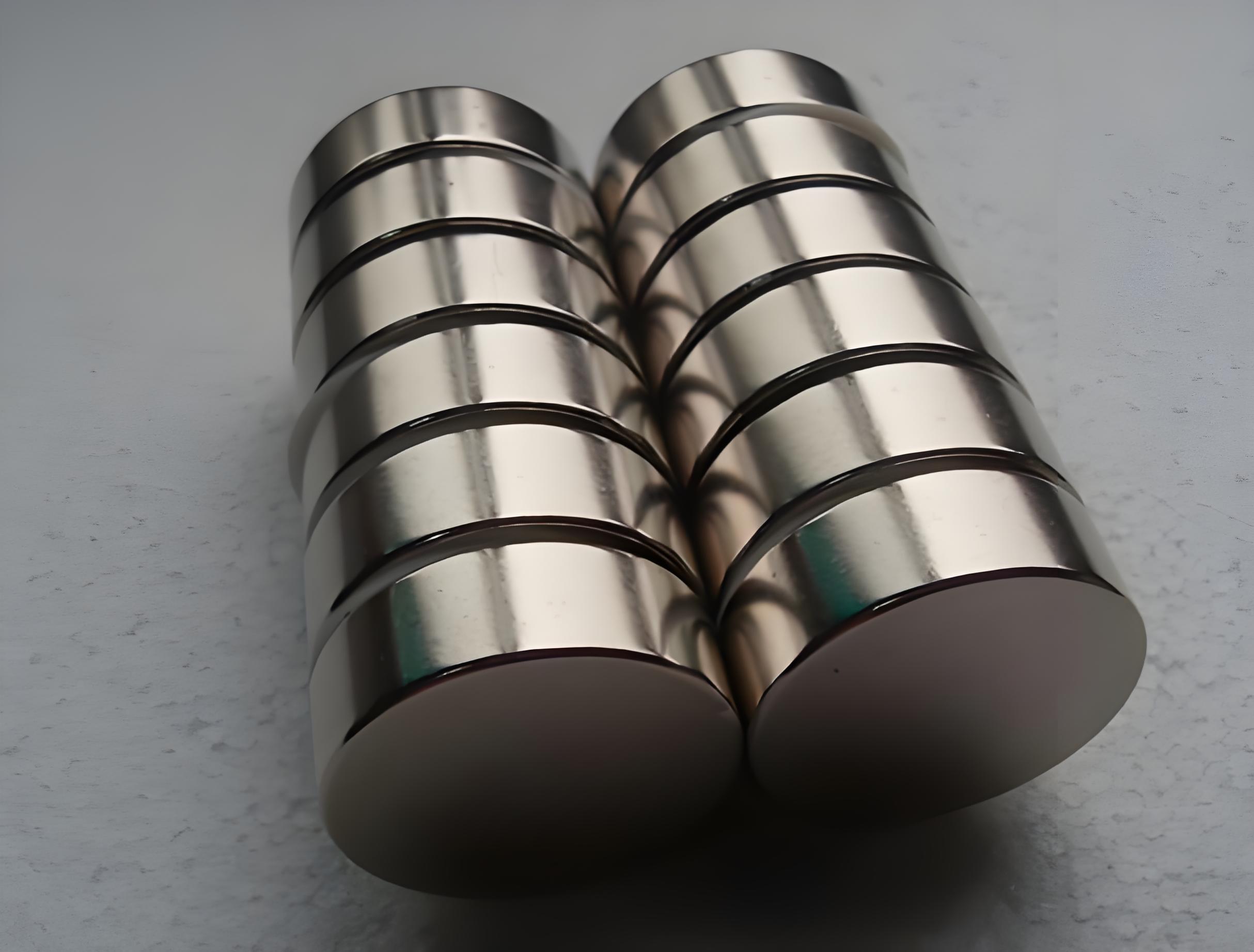

6. Processing ndi pamwamba mankhwala: Maginito a sintered amafunikanso kudulidwa, kupukutidwa ndi makina ena kuti akwaniritse mawonekedwe ndi kukula kwake. Pofuna kupewa maginito kuti asatengeke ndi okosijeni kapena dzimbiri panthawi yogwiritsira ntchito, malo otetezera monga nickel, zinc kapena epoxy resin nthawi zambiri amakutidwa pamwamba pake.

7. Magnetization: Chomaliza ndikupangira maginito maginito kuti ipatse mphamvu yamaginito. Magnetization nthawi zambiri imachitika mu zida zapadera za magnetization, pogwiritsa ntchito mphamvu ya maginito kuti maginito a maginito agwirizane.

Kuvulaza kwamphamvu maginito

Kupha kwa zida zamphamvu zamaginito kumawonekera makamaka m'magawo awa:

1. Mphamvu pazida zamagetsi: Zida zamphamvu zamaginito zimatha kusokoneza magwiridwe antchito a zida zamagetsi, makamaka zomwe zimadalira masensa a maginito. Mwachitsanzo, mafoni am'manja, ma hard drive apakompyuta, ma kirediti kadi, ndi zina zambiri zitha kukhudzidwa ndi mphamvu zamaginito, zomwe zimapangitsa kutayika kwa data kapena kuwonongeka kwa zida.

2.Kukhudza thupi la munthu: Ngakhale zida zamphamvu zamaginito sizipereka chiwopsezo chakupha mthupi la munthu, zimatha kuyambitsa kupweteka kapena kusapeza bwino ngati zitamezedwa kapena kukhudzana ndi khungu. Kuphatikiza apo, zida zamphamvu zamaginito zimathanso kukopa zinthu zachitsulo zomwe zili pafupi ndikuyambitsa kuvulala mwangozi.

3.Impact pa zipangizo zina maginito: Zipangizo zamphamvu za maginito zimatha kukopa ndi kusuntha zinthu zina za maginito, zomwe zingapangitse kuti zinthu zolemera zigwe kapena kuti zipangizo ziwonongeke ngati sizikugwiridwa bwino. Chifukwa chake, mukamagwiritsa ntchito maginito amphamvu, njira zoyenera zotetezera ziyenera kuchitidwa kuti mupewe ngozi zosafunikira.

4.Zokhudza zida zamakina: Nthawi zina, zida zamphamvu zamaginito zimatha kutsatsa zitsulo muzipangizo zamakina, kupangitsa zida kulephera kapena kuzimitsa. Izi ndizowopsa makamaka pazida zolondola komanso zida zamankhwala.

Momwe mungapewere zotsatira za maginito amphamvu

1. Khalani kutali: Sungani zida zamphamvu zamaginito kutali ndi zida zamagetsi, makhadi a ngongole ndi zinthu zina zovuta.

2. Njira zodzitetezera: Valani zida zodzitetezera pogwira zinthu zolimba za maginito ndipo pewani kukhudza khungu.

3. Maphunziro ndi machenjezo: Phunzitsani ana kuti asamasewere ndi zidole zamphamvu zamaginito ndipo onetsetsani kuti amvetsetsa zoopsa zomwe zingachitike.

4. Malangizo a akatswiri: M'madera azachipatala, onetsetsani kuti odwala ndi ogwira ntchito amvetsetsa malamulo a chitetezo cha zipangizo zolimba za maginito ndikuchitapo kanthu zodzitetezera.

5. Kusungirako ndi mayendedwe: Zida zamphamvu za maginito ziyenera kusungidwa m'mitsuko yapadera ndikutetezedwa moyenera panthawi yoyendetsa kuti zisagwirizane ndi zinthu zina.

Kapangidwe kazinthu zolimba zamaginito ndizovuta komanso zofewa zomwe zimaphatikizapo masitepe angapo komanso njira zaukadaulo zamaluso. Kumvetsetsa momwe zimapangidwira kumatithandiza kumvetsetsa bwino ndikugwiritsa ntchito zipangizozi. Panthawi imodzimodziyo, tifunikanso kudziwa kuopsa kwa zinthu zolimba za maginito ndi kutenga njira zodzitetezera kuti tikhale otetezeka.

Nthawi yotumiza: Oct-25-2024